When evaluating cold storage partners, food manufacturers and distributors often find that transportation capabilities become the deciding factor between a good partnership and a great one. The ability to seamlessly integrate temperature-controlled warehousing with reliable transportation services creates efficiencies that standalone providers simply cannot match.

The Real Cost of Disconnected Services

Managing cold storage and transportation through separate providers introduces friction at every touchpoint. Consider what happens when a carrier arrives late to a warehouse managed by a different company: the warehouse faces disrupting its dock schedule or enforcing strict appointment windows that result in detention charges. Neither option serves the customer well.

These coordination challenges multiply with temperature-sensitive products. For ice cream stored at minus-20 degrees Fahrenheit, even brief exposure during dock transfers between separate providers can impact quality. When transportation and warehousing operate under unified management, these critical handoffs become seamless internal operations rather than negotiated transactions.

The hidden costs extend beyond operational friction. Each provider relationship requires separate contracts, invoicing, dispute resolution processes, and performance monitoring. When miscommunication leads to a missed delivery window at a major retailer, finger-pointing between warehouse and carrier helps no one—especially not the customer facing potential chargebacks.

How Integration Creates Operational Excellence

When the same organization manages both warehousing and freight movement, distinct advantages emerge that go beyond solving coordination problems:

Unified Accountability: A single point of contact understands both storage requirements and transportation logistics, eliminating the communication gaps that occur when warehouse staff, dispatchers, and customer service teams work for different companies.

Dynamic Resource Allocation: Integrated providers naturally prioritize their own transportation assets at receiving docks. While third-party carriers face strict appointment windows, company-owned trucks receive the flexibility needed to maintain service levels despite unexpected delays. This same flexibility enables providers to balance margins across services—accepting lower transportation rates to secure valuable storage volume, creating win-win scenarios impossible with separated services.

Consistent Excellence: When drivers regularly serve the same facilities, they develop familiarity with specific customer requirements, dock procedures, and product handling needs. Partners like C.H. Robinson, operating consolidation programs within CORE X GRESS facilities, combine their brokerage networks with dedicated fleet assets, creating a hybrid model that delivers both flexibility and reliability.

Emergency Response Capability: When disruptions occur—a breakdown, missed appointment, or unexpected surge—integrated providers can deploy owned assets as an emergency valve. This safety net proves invaluable during peak seasons or time-sensitive promotions.

Strategic Value Across Business Models

Different business models benefit from integrated services in distinct ways:

High-Volume Manufacturing Operations

Large-scale food manufacturers, particularly those producing temperature-sensitive products, require reliable inbound delivery of packaging materials alongside consistent outbound distribution. These operations benefit from dedicated fleet services that maintain supply chain control while reducing vendor management complexity. When production runs on tight schedules, having transportation assets that prioritize your facility’s needs becomes invaluable.

Mid-Size Regional Producers

Regional protein processors and specialty food manufacturers often operate with leaner teams that cannot afford disruptions. When unexpected changes occur—whether a provider terminates service or seasonal demands spike—the ability to quickly deploy both storage capacity and transportation resources enables business continuity. These businesses particularly value the operational simplicity that comes with integration.

Seasonal and Surge Operations

Food companies managing holiday surges or promotional spikes need flexibility that separated services struggle to provide. Integrated providers can dynamically shift resources between storage and transportation based on immediate needs. This operational agility enables creative solutions during peak periods that would be impossible when negotiating with multiple vendors.

Technology Amplifies Integration Benefits

Modern integration success depends on technology infrastructure. Single warehouse management systems across networked facilities enable real-time inventory visibility and transportation planning. Temperature monitoring systems that span both storage and transit provide unbroken cold chain documentation.

Advanced facilities like CORE X CROWN leverage automation technologies that accelerate truck turnaround times. When the same organization controls both automated storage systems and transportation assets, scheduling optimization reaches levels impossible with fragmented providers. Loading sequences can be optimized in the warehouse specifically for multi-stop delivery routes, with real-time adjustments based on traffic and delivery window changes.

Making the Right Partnership Decision

Evaluating integrated cold storage and transportation services requires assessing several factors:

- Volume Concentration: Higher volumes through specific facilities justify dedicated transportation resources

- Temperature Requirements: Products requiring strict temperature control benefit from unified accountability

- Delivery Complexity: Multi-stop routes and tight delivery windows favor integration

- Growth Trajectory: Expanding businesses value the scalability of integrated services

- Regional Focus: Concentrated geographic distribution patterns maximize integrated service value

The Path Forward

As supply chains face continued pressure to reduce costs while improving service, integrated cold storage and transportation offer clear strategic advantages. The elimination of handoff friction, improved accountability, and operational flexibility create measurable benefits for food manufacturers and distributors.

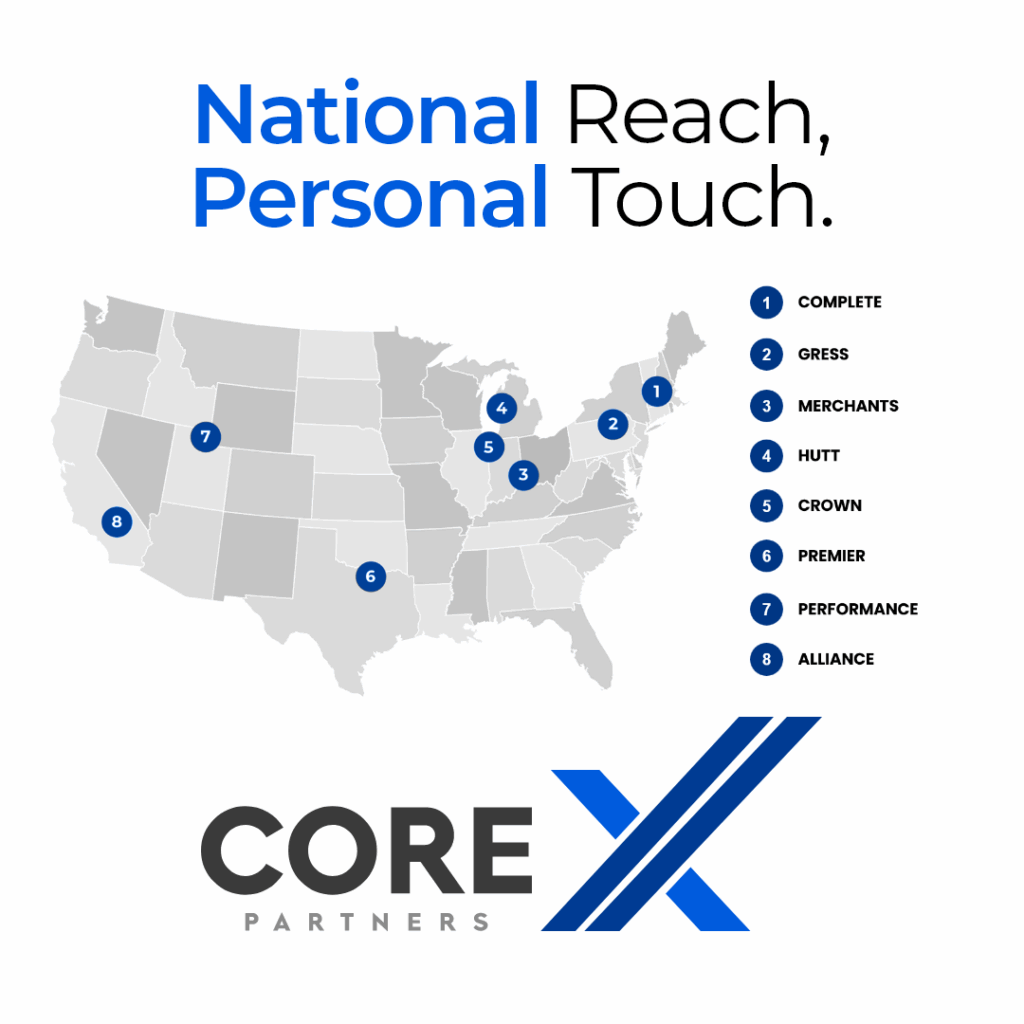

At CORE X Partners, this integration philosophy drives everything from fleet operations at facilities like CORE X HUTT to the collaborative partnerships with logistics providers across our network. By eliminating artificial boundaries between storage and transportation, we create unified solutions that reduce complexity and drive excellence throughout the temperature-controlled supply chain.

For companies evaluating their cold chain strategy, the question isn’t whether to consider integrated services, but how to identify partnerships that align transportation capabilities with specific operational needs. The answer often lies not in fleet size or automation level, but in a provider’s ability to seamlessly coordinate both elements in service of your unique requirements—turning what was once a source of friction into a competitive advantage.