Dallas-Fort Worth is one of America’s largest cold storage markets—and for good reason. The Metroplex’s 8 million residents, strategic transportation infrastructure, and business-friendly climate have attracted dozens of facilities. But when three cold storage facilities sit within 100 yards of each other, location stops being a differentiator.

Competition is high in the Dallas-Fort Worth cold storage arena; everyone has access to the same interstates and rail lines. What separates facilities is customer service—and the people who deliver it.

Ron Buford has seen this evolution firsthand. Over his 46-year career in DFW cold storage, he’s watched the market grow from a single facility in 1971 to one of the nation’s densest concentrations of warehouse space. Now, as the leader at CORE X Premier in Burleson, he operates a facility with competitors literally on both sides.

His perspective on what matters? “There’s a lot of cold storages in town. And the only thing that we’ve got they don’t is us.”

Why Dallas-Fort Worth Became a Cold Storage Hub

The Dallas-Fort Worth Metroplex didn’t become a major cold storage market by accident. Multiple factors converged to create ideal conditions for temperature-controlled warehousing.

Transportation infrastructure provides the foundation. Interstate 35 runs north-south through the region, connecting Mexico to Canada. Interstate 20 crosses east-west. Major rail lines serve the area. This positioning gives DFW facilities efficient access to distribution networks across the country.

The labor market offers another advantage. With approximately 8 million people in the Metroplex—growing by roughly 400 people per day—cold storage operators can find experienced warehouse workers, equipment operators, and logistics professionals. Population density supports 24/7 operations and multiple shifts.

Business climate matters too. Texas has no state income tax, which reduces operational costs compared to other major markets. The state’s regulatory approach generally favors business operations, making facility development and expansion more straightforward than in heavily regulated markets.

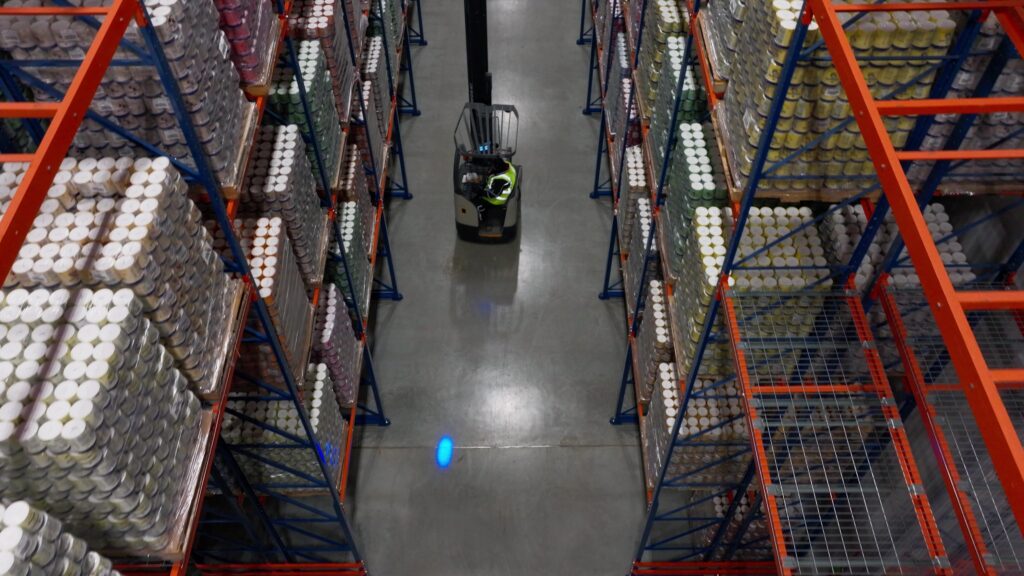

The cold storage infrastructure itself has evolved dramatically. When Ron started in the industry in 1971, facilities featured 18-foot ceilings. Modern warehouses reach 50 feet, enabled by technological advances in racking systems, material handling equipment, and automated storage solutions. This evolution has multiplied storage capacity on the same footprint.

In Summary: DFW’s advantages are real—and everyone knows it. Which is why competition is fierce, and why the factors that initially attract companies to the market don’t actually determine which facility they choose.

DFW’s Cold Storage Market

Ron’s perspective on market competition comes from watching it intensify around his facility. “We were the only ones down here nearly four years ago,” he explains about CORE X Premier’s Burleson location. “And then all of a sudden there were three of us.”

Corporate facilities vs. independent operations represent different service approaches in this environment. Large national cold storage companies emphasize standardized systems, technology platforms, and network-wide protocols. These capabilities serve certain customer needs well, particularly for companies requiring identical service across multiple markets.

The trade-off often comes in operational flexibility. Corporate facilities typically require multiple approval layers for non-standard requests. When a customer calls at 4 pm with an urgent need, the response depends on who’s available in a decision-making hierarchy that may not be on-site.

Family-owned operations, by contrast, typically feature decision-makers who understand the facility’s capabilities intimately and can respond immediately. This doesn’t make one model superior across all dimensions—it makes the operational model a meaningful choice factor once location advantages are equal.

Ron’s observation about his competitors rings true: they all have good buildings, modern equipment, and professional teams. The location benefits that brought them to Burleson are shared by everyone in the immediate vicinity.

In Summary: Location gets you considered in DFW’s cold storage market. Service gets you the business—and keeps it. Most customers choose based on operational responsiveness, not proximity to highways.

What “Customer Service” Means in Cold Storage

“Customer service” in cold storage isn’t pleasant interactions or responsive email replies. It’s operational capability when customers face urgent problems. Two situations at CORE X Premier demonstrate the difference.

The 130-Truckload Test

A customer called Ron with an unusual request. They needed to move 130 truckloads of product immediately. The customer worked with one of the country’s highest-rated food service companies. They needed confidence that Premier could handle the volume without disruption to their distribution schedule. “At the drop of a hat,” Ron explains, “he was just really, really thankful that we had provided the level of service.”

This had little to do with available space. It required warehouse staff who could adjust receiving schedules, equipment operators who could work efficiently under time pressure, and logistics coordination to manage 130 dock appointments without creating bottlenecks. The customer’s satisfaction came from execution, not promises.

The 4pm Emergency

“It happens at least a couple times a week,” Ron notes about a common scenario: a customer calls late in the day because a load was rejected at its destination. Whatever the cause, the customer now has a truckload of temperature-sensitive product that needs immediate cold storage. It’s after 4 pm. Most facilities’ decision-makers have gone home.

At Premier, the response doesn’t wait for Ron to weigh in. “Our staff,” he explains, “they don’t have to wait and find me and say, Ron, what can we do? They know what to do.”

The team has the authority to accept loads, assign storage space, and coordinate receiving immediately. The customer gets a solution while their product maintains temperature integrity. This happens one to two times per week because the operational model supports it.

This type of service requires more than nice people. It requires:

- Systems that enable immediate yes: Warehouse management systems that show real-time space availability, allowing staff to make commitments without verification delays

- Empowered employees: Team members who understand capacity limits and pricing structures, authorized to make decisions within defined parameters

- Operational flexibility: Receiving processes that can adjust to unexpected volume without disrupting scheduled appointments

“We’re a can-do facility,” Ron states simply. “We’re going to listen to what the customer says they need.”

In Summary: Customer service in cold storage means operational responsiveness—empowered people plus systems that enable immediate solutions when customers face urgent problems.

The “Family-Owned Business” Operating Model

CORE X Premier operates within a national network but maintains what Ron describes as a “family-owned business” approach. The distinction matters in how the facility responds to customer needs and how employees engage with their work.

“We operate like a family-owned business,” Ron explains, “and we’ve tried to create a sense of ownership with the people… because if you’re not doing it right and you’re not making the money, then that affects everybody.”

This philosophy manifests in several operational practices:

Transparency about business performance: Employees understand how the facility’s financial performance affects their opportunities. When the operation succeeds, team members benefit. When challenges arise, they’re part of solving them rather than receiving top-down directives.

Decision-making authority: Staff members handle situations without waiting for management approval within their areas of responsibility. The 4pm emergency saves happen because receiving supervisors can commit space and resources immediately.

Long-term thinking: Ron’s approach emphasizes “we want to grow with you” rather than transactional relationships. When customers expand operations, they know Premier will accommodate increased volume. When they face temporary setbacks, the facility works with them rather than rigidly enforcing minimum volume requirements.

Ron’s team-building philosophy supports the model: “I’ve been successful over the years in being able to build teams,” he explains, “and I try not to get in their way, but I’m here to support them.”

The statement reveals key CORE X priorities: hire capable people, give them authority, remove obstacles rather than create them. When challenges arise—and they do in any warehouse operation—the team addresses them without bureaucratic delays.

In Summary: The family-owned business operating model, where the employees are the family, enables the responsiveness and flexibility that differentiate service for a cold storage warehouse.

How to Choose a Cold Storage Partner in DFW

When evaluating cold storage options in the Dallas-Fort Worth market, location advantages become secondary considerations once you’ve identified facilities in your preferred area. These criteria help assess operational capability:

- Test Their Responsiveness

Ask how they would handle a hypothetical urgent need: “If we have a rejected load arriving at 4 pm today. Can you receive it?” The response reveals operational capability and decision-making authority.

Positive indicators:

- Staff can check capacity and commit immediately

- They ask relevant questions about temperature requirements and volume

- They explain receiving procedures clearly

- They provide direct contact information for day-of coordination

Warning signs:

- Must check with management and call back

- Can’t provide clear pricing until reviewing with corporate

- Suggest calling back during normal business hours

- Ask About Their Worst Day

Every facility faces challenges—equipment failures, power outages, unexpected volume spikes, and weather emergencies. How they handled their worst situations reveals more than descriptions of their best ones.

Questions to ask:

- What was your most challenging customer situation in the past year?

- How did you resolve it?

- What did you learn from it?

- How have you changed operations based on that experience?

The answers demonstrate problem-solving capability and willingness to adapt.

- Look for Market Tenure

How long has the facility operated in DFW specifically? Experience in other markets doesn’t necessarily translate to understanding local distribution patterns, labor markets, and customer needs.

Consider:

- Years in current location

- Staff tenure (high turnover suggests problems)

- Long-term customer relationships

- Knowledge of local market conditions

New facilities may offer modern infrastructure but lack the operational wisdom that comes from handling thousands of unique situations in a specific market.

Partnership Over Square Footage

In a market as cutthroat as Dallas-Fort Worth, cold storage options are abundant. Location advantages—transportation access, labor availability, business climate—are real but widely shared among facilities.

Ron Buford’s perspective after 46 years in the market remains consistent: “We want to grow with you.”

CORE X Premier represents regional expertise combined with a people-first operational approach. The facility benefits from CORE X Partners’ national network while maintaining the responsiveness and flexibility that competitive markets demand.

Learn more about CORE X Premier’s approach to cold storage in Dallas-Fort Worth.